Calendering & Flooring

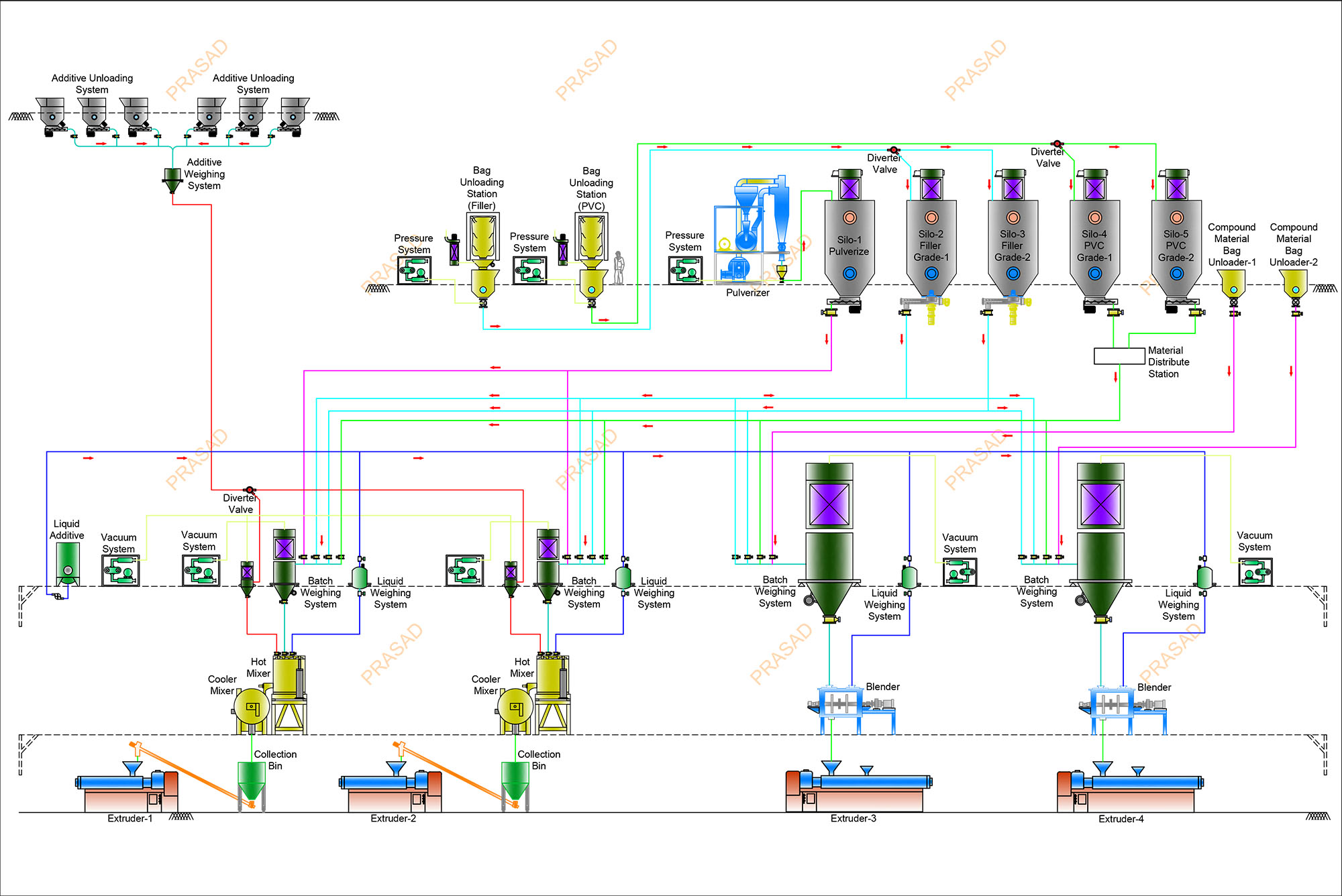

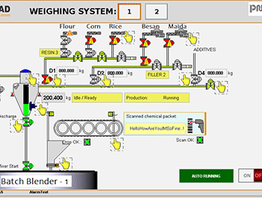

Due to very high % dosing of Liquids, Calendar industries are using huge batch sizes starting from 1500 - 5000 kg/ batch. Our automation system delivers complete batch of PVC, CaCO3 & Liquids in automatic mode and integrates seamlessly with blender.

Typical SCP plants required almost 55-60% of filler loading. Our system provides dust free filler handling with central storage silos & closed loop integration with Mixers. Our recipe maker system gives edge over multiple additives dosing on-line over mixers.

Typical SCP plants required almost 55-60% of filler loading. Our system provides dust free filler handling with central storage silos & closed loop integration with Mixers. Our recipe maker system gives edge over multiple additives dosing on-line over mixers.

Benefits & Technical Specifications

- No spillage & dusting

- Les manpower required

- Multiple recipe distribution from one recipe maker

- Hands on experience for 210 T / Day profiles production

- 800 Ton storage in just 75 Sq. Meter

- Complete solution for reprocess / pulverised feeding back into process